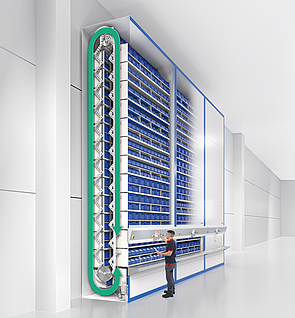

Hänel offers high-tech systems such as the Rotomat®, the Lean-Lift® and the Multi-Space® for automated tool storage. Alongside ergonomic design, tool protection and many system innovations, Hänel assigns top priority to the cost-effectiveness of these solutions.

Hänel systems can save up to 60% of the floor space needed for storage, while dramatically reducing the time needed to access tools. Innovative systems like the Hänel Lockomat® and the Hänel VendiShelf system for the Hänel Lean-Lift® also ensure error-free retrieval and safeguard valuable tools against unauthorized access and theft.

Our trade fair schedule is in the planning stage. Details about our participation in future trade fairs will be available here soon.

Many business enterprises around the world use Hänel storage systems to increase the cost-effectiveness of their tool storage and provisioning. Hänel lift systems fully utilize the vertical space available for height-optimized tool storage within a small footprint. The result is maximum storage capacity and less required floor space. And that saves money!

Hänel systems automatically bring tools to the access area in just seconds - the tools can then be retrieved at the optimum ergonomic height. Hänel lifts can be operated with as stand-alone solutions with integrated Hänel tool management software, or they can be used in conjunction with overarching host systems based on most tool management solutions now available.